Willkommen bei der Dowaldwerke GmbH

Die Dowaldwerke GmbH ist ein Unternehmen der Richard Grießbach Holding, einem inhabergeführten, mittel-ständischen Firmenverbund mit rund 350 Mitarbeitern.

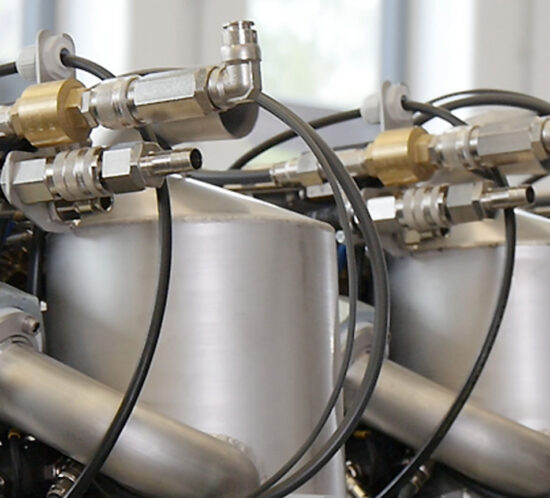

In unserem Geschäftsbereich Bahntechnik gehören wir zu den Marktführern. Hier entwickeln und produzieren wir Vakuumtoiletten, Innentürsysteme, Trennwände und Einstiegshilfen für die großen Schienenfahrzeughersteller Europas. Im Geschäftsbereich Hydraulik produzieren wir in erster Linie Hydraulikzylinder für den Einsatz in Land- oder Baumaschinen und anderen Fahrzeugen.

PRODUKTE

Unsere Produkte für Ihre höchsten Ansprüche. Sehen Sie hier einen Auszug unserer möglichen Produkte. Sie suchen ein individuelles Produkt? Bei uns finden Sie die Lösung, die zu Ihren Anforderungen passt.

LÖSUNGEN

Entwicklung und Fertigung aus einer Hand. Wir unterstützen unsere Kunden bereits bei der Entwicklung Ihres neuen Produktes. Je nach Anforderung entwickeln wir eigenständig oder nach Ihrer Spezifikation Ihr neues Bauteil.

UNTERNEHMEN

Die Dowaldwerke GmbH, mit Sitz in Dippoldiswalde bei Dresden, ist ein etablierter Zulieferer der Schienenfahrzeugindustrie. Zu den Kunden gehören die größten europäischen Schienenfahrzeughersteller.